Why the Trimble Layout Method Beats Traditional

Trimble technology is being used more and more frequently during the layout process on construction sites. There are several advantages to the Trimble layout method that contribute to its growing use in the industry.

First and foremost, Trimble layout is much faster than traditional layout. One person can complete a layout faster than two people using traditional layout techniques. This is a huge cost savings for projects and helps contractors remain within their budgets and on schedule. The Trimble layout approach is also more precise. Even the most complex designs can be laid out with accuracy which eliminates rework and improves quality.

How does Trimble Layout Work?

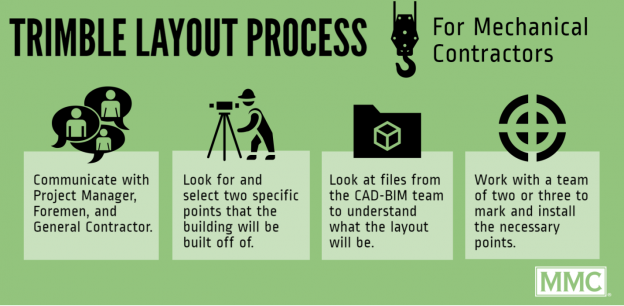

The layout process begins with the field layout superintendent getting in contact with either the general foreman or project manager on site and ensuring they have a contact through the General Contractor for layout. Then they look for at least two specific points they can use that the building will be built off of. The further away the two points are from each other, the better. The field layout superintendent sets up their equipment so they can shoot those two selected points with a 90° angle.

Once they’ve done this, they can then create new points of their own and can move their equipment almost anywhere they want. As long as they have two points, old or new, that they know are accurate with the building and that they can see, they can go anywhere inside or outside the building including the basement and roof. Once they reach this point, the CAD-BIM department gets them the files for what they are laying out and they get to work.

The field layout superintendent, usually with the help of one or two coworkers, will begin to mark and install the points. Once this laying out process begins, the crew might lay out as many as six or seven hundred points in a single day.

“The important thing is to stay level and accurate, things shift, ground, buildings – you have to be mindful of that. If you know your initial setup is good and you check occasionally throughout the day on a set control point to make sure you are still accurate, you should be set.” – Field Layout Superintendent at MMC